How well are you equipped to handle down equipment, replace worn parts, or ensure you have the necessary spare parts on hand? Today’s market poses unique workforce challenges that may leave you short-handed, but you still have a job to do and product to get out the door.

That's where our service team comes in. We cover the aftermarket side of things like:

How much do you know about your robot's health? What is the condition of the existing grease? How many times has each axis detected a collision and why? This information gives insight to the overall health of your equipment; allowing issues to be addressed proactively.

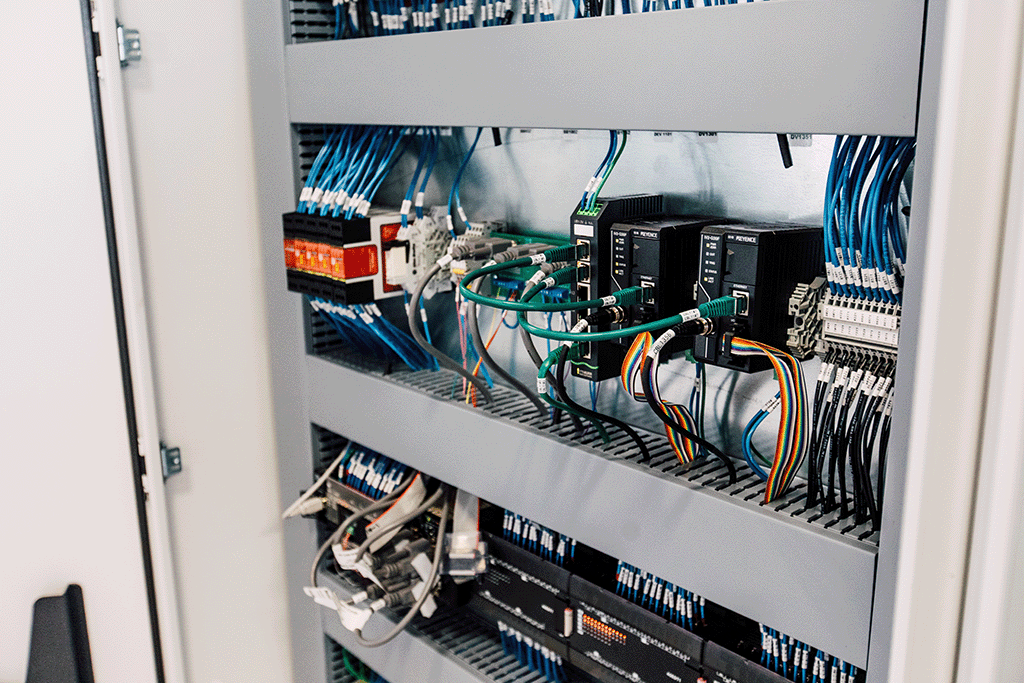

We promise not only to grease the gears and change the batteries, but also to conduct a thorough inspection of each robot and controller. You'll receive a detailed report outlining this type of critical data, along with recommendations to proactively address any issues found.

What can you do to reduce downtime and prolong the life of your equipment besides routine Preventive Maintenance visits? A Service Agreement. Our customers appreciate our flexible, no-size-fits-all approach.

Is your equipment mechanically sound, but still not performing efficiently? Sometimes, a few program tweaks can make all the difference. Whether you are looking to improve cycle time or add a new part, we can help.

We promise to listen, offer thoughtful insight, and work with you to achieve your performance goals.

Do you have new equipment or has your team changed and grown? Statistics show that hands-on training in small class sizes provides the best learning and information retention. We offer classes at your facility or ours, whichever is most convenient for you.

We promise to keep class sizes small and dedicated to only your team to ensure individual attention.

Looking to upgrade or repurpose your existing equipment? Whether you need a small retrofit or massive undertaking, the Mission team is at your service. Mission Design & Automation is your full-service automation company.

How detrimental is down time to your operation? Are you able to get by for a couple of days or even weeks if your equipment crashes or fails? Today’s supply chain issues make it even more crucial to have critical spare parts on hand. If you are in need of spare parts or need help determining what you should stock, give us a call.

We promise to help you develop a plan for spare parts by recommending critical parts, common crash replacements, wearables, and long lead time items.

Mission aimed to educate about the manufacturing industry by offering students hands-on experiences in manual robot controls and conversations dispelling common stereotypes about manufacturing jobs.

read more

The mission of RoboWeek is to inspire students of all ages to pursue careers in STEM fields—science, technology, engineering, and mathematics. RoboWeek aims to share the excitement of robotics with educational events, activities, and programs across the United States. Mission Design & Automation is proud to support the initiatives of Robotics Week by sponsoring four FIRST Robotics teams at local high schools.

read more

At the beginning of 2023, Mission Design & Automation recognized an opportunity for our team to make a tangible difference within our local community.

read more